Process Factory is a concept created by Link Consulting that allows optimizing organizations’ digital process transformation, through the dematerialization of their procedures.

Process Factory is a concept created by Link Consulting that allows optimizing organizations’ digital process transformation, through the dematerialization of their procedures.

Thus, it is intended to optimize and streamline the entire flow automation process, reduce times and costs associated with its implementation.

The factory concept is based on two main aspects:

● Transformation

● Monitoring and Corrective Maintenance

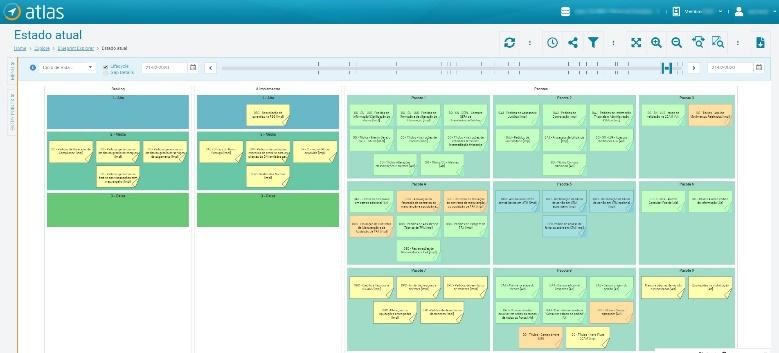

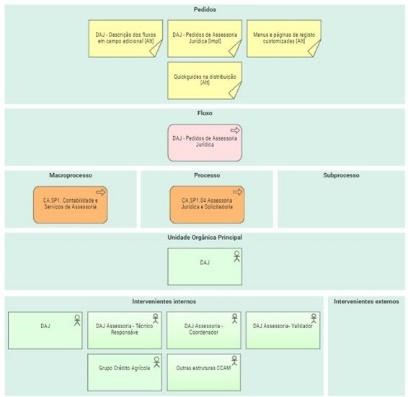

The transformation aspect introduces an iterative perspective and begins with the identification of requests for the implementation of processes within the different areas of the organization or with the evolution of processes already implemented. Orders are placed directly on the Atlas platform and are then analyzed, classified and inserted in the backlog.

After prioritizing, work packages are defined. As a result, the design phase begins and then the process implementation in the tool occurs. Once accepted, the monitoring and handover phase of the work package sets in. Work packages can also contain change requests for processes already in production.

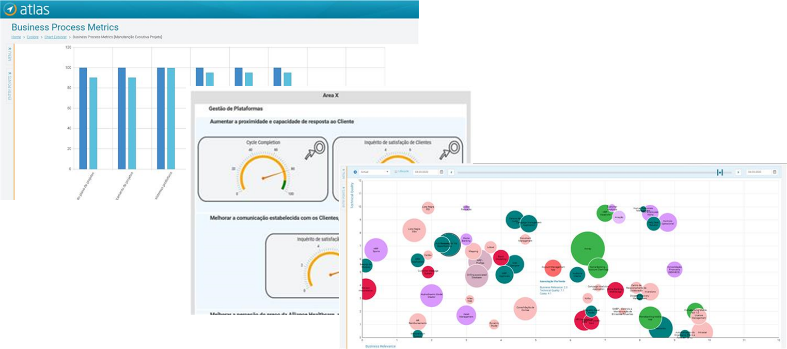

The monitoring and corrective maintenance aspect allow both the customer and Link consulting teams to control the status of orders, manage backlog as well as factory work packages.

The Process Factory has a dedicated team that was born from the area of implementation of our workflow solution.

In terms of implementation, the team uses a methodology based on 2 main tools – edoclink and Atlas – both developed by Link Consulting, the first aims at implementing the business processes themselves and the second, being a business architecture tool, ensures the management, monitoring and control of requests for their implementation

With this commitment, Link Consulting intends to evolve its documentary workflow implementation segment this year.